FANUC is the world leader in industrial robots and numerical controls, playing a key role in industries where precision and reliability are essential. With more than 70 years of experience, FANUC has built a strong reputation in automation.

“FANUC is built on a solid Japanese foundation, where strictness, perfection and precision guide everything we do,” says Dr. Bob Struijk, CEO of FANUC Nordic. “Customers trust our products because they deliver 99.99% reliability, allowing them to focus on their own production and efficiency.”

Why FANUC Stands Out

One of

FANUC’s biggest strengths is that it develops and manufactures all major

components in-house – from servo motors and encoders to controls, hardware,

software, and automation systems. By relying on fewer components and lean

technology, FANUC provides solutions that are reliable, predictable, and easy

to maintain. “Combine this with having application and service engineers in

the local countries to support the customers makes it the proper choice”

says Struijk.

FANUC also practices “lights-out automation” in its own factories, where about 6,000 robots work alongside just 800 human operators. This creates nearly fault-free production, leading to maximum uptime and minimal downtime for customers. On top, the solution to solve the many internal automation challenges are used to develop industrial automation solutions for the market. In example, embedded robotic force sensors and 2D and 3D vision systems from FANUC were born in its own factories.

A Wide Range of Products

FANUC’s portfolio includes:

- CNC control systems, 5-axis simultaneous

- Industrial robots and cobots

- Vertical machining centers for milling, drilling, lathe

- Fully electric injection moulding machines

- Wire-cut EDM machines

- Drive systems and Laser technology

With more than 160 robot models, ranging from small to heavy-duty machines capable of handling up to 2.3 tonnes, FANUC offers solutions for almost any application. Many robots and cobots are also approved for food handling, harsch environment, explosion proof Atex and cleanroom environments.

Meeting Labor Challenges with Automation

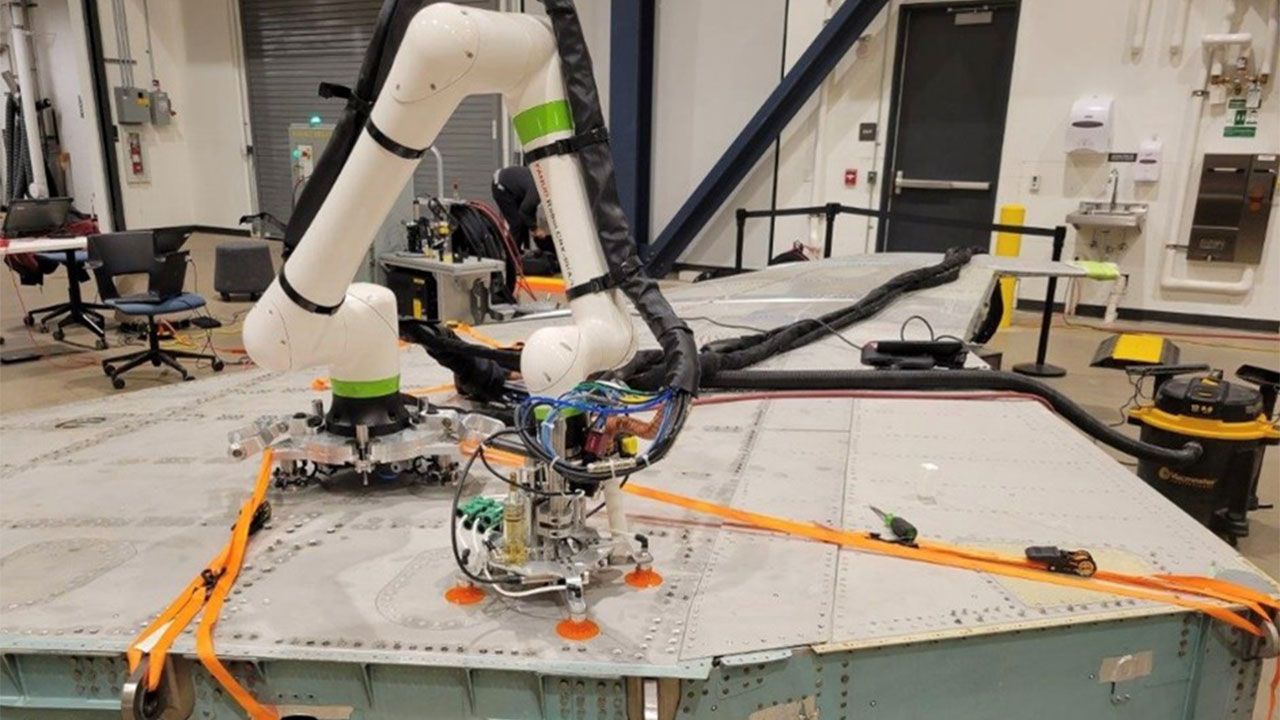

With many

industries facing a shortage of skilled workers, the need for automation has

never been greater. FANUC provides robotic solutions for drilling, riveting,

painting, handling, welding, and more – all with consistent, high-quality

results.

Training for the Future

To help

customers maximize their investment, FANUC Academy offers training programs for

all levels – from beginners to advanced professionals. Training can take place

at FANUC Academies in Sweden, Denmark, and Finland, or directly at the

customer’s site. By investing in skills development, customers unlock the full

potential of FANUC’s products.